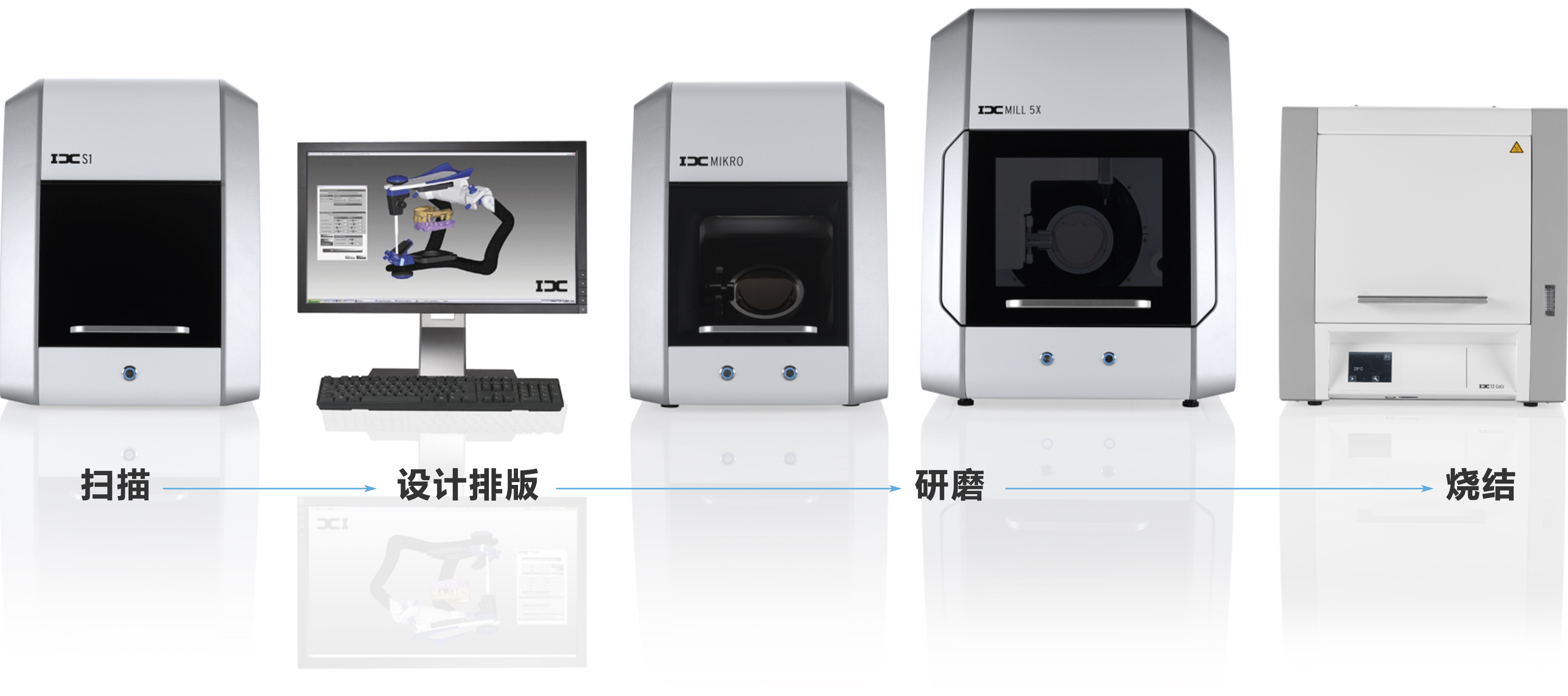

Creating a digital dental restoration center for you

IDC provides a complete set of systematic solutions from scanning to design, from grinding to sintering, paired with original consumables, to minimize potential errors during the process and provide high-quality detail processing

Grinding - Multi directional and multifunctional

The IDC series of grinding equipment covers four axis and five axis equipment, which can meet the different needs of dry grinding, wet grinding, and even dry wet dual use. It can not only achieve rapid repair by the chair, but also provide complex restoration solutions for the technician room.